Safe Handling Guidelines

FIBC

Safe Handling Guidelines

To avoid mishaps that could endanger your workers’ safety or harm the materials you’re working with, it is critical to follow specific standards and guidlines when using your FIBCs.

Ensure a safe working load (SWL)

First and foremost, double-check that the FIBC you're using is appropriate for the substance you want to transport. Make sure to inspect crucial components of the huge bag, such as whether or not it has a lining and its maximum weight capacity, before filling it. You must not exceed the maximum weight that the large bag is designed to hold, since this may cause the bag's foundation to strain or even tear.

Follow safe filling practices

Make sure the place you're filling the FIBC in is safe for the material you're working with before you start. Before you start loading the bag, make sure it's on an even surface. Pre-inflate your big bag's liners and extend them past the fill spout for optimal convenience and safety. Fill only to the recommended level, and gently shake or vibrate the material to let it settle.

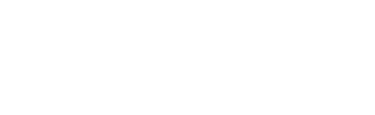

Follow safe lifting practices

If your FIBC has four loops, make use of them all while suspending it. This will equal out the load and offer optimal stability during the lifting/moving procedure, reducing the risk of a rip. Read the bag manufacturer's instructions to learn how to handle the bag properly when using hooks, forklifts, and other handling equipment. Do not allow any worker or supervisor to stand immediately beneath a hung FIBC, regardless of the precautions you take to lift or move the huge bag. If there is no risk of stuff dropping out during movement, they may be allowed to stand by it.

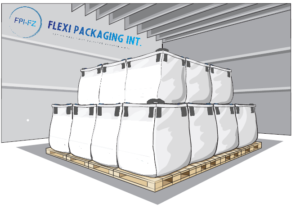

Follow safe storage and transport practices

When storing or transporting a filled FIBC, make sure it’s on a pallet with no sharp edges, nails, or other potentially damaging surfaces. To preserve the bag from the sun and other weather conditions, store it and transfer it in a covered area.

When moving FIBC, make sure it is properly fastened and that it is not subjected to rapid stops or lifts. If you need to stack large bags one on top of the other, make sure the FIBC is capable of doing so.

Always priortise safety

Safety should always come first, even if it means sacrificing convenience or expense. Always put your workers ahead of your material and avoid taking any moves or acts in a rush.

DO'S

DONT'S

- Before lifting bag, check your bag for any damage.

- Read & follow the handling instructions on the label.

- Make sure that the bag is stable

- Take measures in regard to dust control.

- Use lifting equipment of sufficient capacity to take the load.

- Make sure that the edges of fork lift tines are rounded and not sharp.

- Adjust fork lift tines to the correct width for the bag being handled.

- Keep the fork lift tines level when lifting and carrying bags.

- Transport bags with care and avoid the load swaying.

- Make sure crane hooks are of adequate size and well rounded.

- Protect the bags from rain and prolonged sunlight.

- Don’t exceed safe working loads under any circumstances.

- Don’t stop or start suddenly during transportation.

- Don’t subject bags to bouncing or to sudden lifts or stops.

- Don’t allow personnel under a suspended bag.

- Don’t allow the bag to project over the side of a vehicle or pallet.

- Don’t tilt the mast of the fork lift forward.

- Don’t drag the bag against the floor or any sidings.

- Don’t withdraw fork lift tines before relieving the load on the fork lift.

- Don’t stack bags unless sure of stability.

- Don’t use second hand bags or refill single-trip bags.

- Don’t lift bags by steel wires.